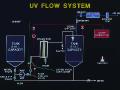

Enhanced Oxidation. Employed on-site pilot-scale technology that combined the oxidative powers of UV light, ozone, and hydrogen peroxide as an alternative to off-site disposal of toxic leachate.

Enhanced Oxidation. Employed on-site pilot-scale technology that combined the oxidative powers of UV light, ozone, and hydrogen peroxide as an alternative to off-site disposal of toxic leachate.

Reverse Osmosis. Ran pilot-scale reverse osmosis to separate noxious compounds from the leachate's water.

Reverse Osmosis. Ran pilot-scale reverse osmosis to separate noxious compounds from the leachate's water.

Leachate Pretreatment. Designed and built a pilot-scale system in the field for the precipitation, flocculation, clarification, and filtration of an industrial landfill leachate prior to reverse osmosis and enhanced oxidation treatments.

Leachate Pretreatment. Designed and built a pilot-scale system in the field for the precipitation, flocculation, clarification, and filtration of an industrial landfill leachate prior to reverse osmosis and enhanced oxidation treatments.

Biodegradation. Created biodegration soil columns to establish the efficacy of biodegradation in removing phenol and cresols.

Biodegradation. Created biodegration soil columns to establish the efficacy of biodegradation in removing phenol and cresols.

Passive Evaporation. Devised bench-scale passive evaporation of contaminated soil to test its efficacy in removing phenol and cresols.

Passive Evaporation. Devised bench-scale passive evaporation of contaminated soil to test its efficacy in removing phenol and cresols.

Soil Washing to Remove Phenol and Cresols. Oversaw bench-scale soil washing to test its ability to remove phenol and cresols from soil. Then co-designed the full-scale treatment that successfully removed phenol and cresols from soil.

Soil Washing to Remove Phenol and Cresols. Oversaw bench-scale soil washing to test its ability to remove phenol and cresols from soil. Then co-designed the full-scale treatment that successfully removed phenol and cresols from soil.

Encapsulation. Immobilized creosote and pentachlorophenol in wood treatment facility soil to minimize contaminant mobility.

Encapsulation. Immobilized creosote and pentachlorophenol in wood treatment facility soil to minimize contaminant mobility.

Steam Injection. Developed a site selection process to best location an innovative in-situ technology that removes soil contaminants.

Steam Injection. Developed a site selection process to best location an innovative in-situ technology that removes soil contaminants.

Site Closure. Reduced the risk of exposure to nearby residents by finding overlooked toxics during a site closure.

Site Closure. Reduced the risk of exposure to nearby residents by finding overlooked toxics during a site closure.